Industrial Uses of Thermocouples

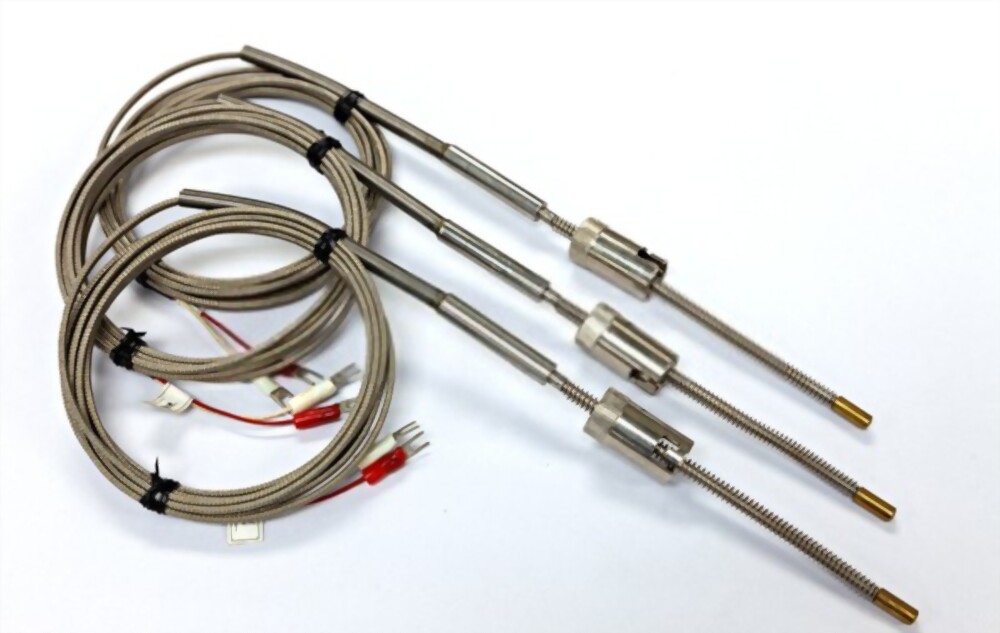

Thermocouples are two dissimilar metal wires that produce a small voltage and current only when joined together at both ends. The temperature gradient across the wires causes an emf to be generated. Thermocouples can detect changes in temperature and convert them into electrical potentials sufficiently large enough to allow their detection and measurement. Below are different industrial uses for thermocouples:

Detecting Flammable Gases With Flame-Type Thermocouples

One of the most common usages of thermocouples is sensing flammable gases such as methane, ethane, propane, acetylene, etc., which explode easily if ignited by heat or open flames. In the past, a manometer was used to measure the pressure of a gas. However, it can be very inaccurate because of its dependence on gravity for proper operation.

Temperature Measurement In Flammable Atmospheres

A flame-type thermocouple is typically used as a temperature sensor in explosive atmospheres due to its insensitivity to minor pressure changes and other factors which might affect manometers or other sensors. It consists of two thin metal wires joined together at one end, usually flanged or pointed.

The free ends are inserted into a special ceramic tube containing a suitable insulation material such as mica and coal dust. This tube is designed to withstand high pressures and temperatures gradually increasing from room temperature at one end to a few hundred degrees Celsius at the other.

Heating And Cooling (Industrial Applications)

Thermocouples can be used as automated heating elements in industrial furnaces where there is a need to regulate or control temperature changes to within far less than 1°C. This is due to its ability to respond to changes in temperature rapidly; thermoelectric power, which reaches up to several kilowatts per meter of wire length; and relatively small size and weight, making it suitable for use in various equipment such as conveyor belts or annealing cabinets.

Measurement Of Fluid Temperature

With the aid of narrow-bore tubing, two flat metal strips are wound helicopter around a rod made from the same material as the sensor wire. One strip is connected to the positive and the other to the negative terminals of a measuring instrument, such as a voltmeter. In this way, it is possible to measure very small temperature differences between the fluid flowing in a pipe or duct.

Temperature Measurement In Medical Thermometers

The principle of using two dissimilar metals joined at both ends also applies to medical thermometers. Mercury and copper-constantan thermocouple junctions are typically used due to the varying sensitivities: mercury has high sensitivity, and copper-constantan junctions have low sensitivity. However, electrical connections for this type of thermometer must be properly insulated since mercury is highly corrosive and toxic.

In the past, glass thermometers were made by filling a long narrow tube with mercury and sealing one end. The liquid level was marked on the tube for reference. Thermocouples are used in various industrial applications, such as detecting flammable gases, controlling the temperature in furnaces, measuring gas pressure, heating elements in annealing cabinets, and medical thermometers.

The devices produce a small voltage and current only when certain temperature gradient conditions across the wires exist within each sensor. This varies depending on the type of material used to construct it and what its application is.