Why should machining companies use CAD software?

Machining is entering a new era with the introduction of new technology, specifically CAD. This computer-aided design software allows producers to create an exact model for their products, including holes and certain specs. You can easily use CAD software, and anyone can learn about it provided they spare some time. The following are reasons why machining companies use CAD:

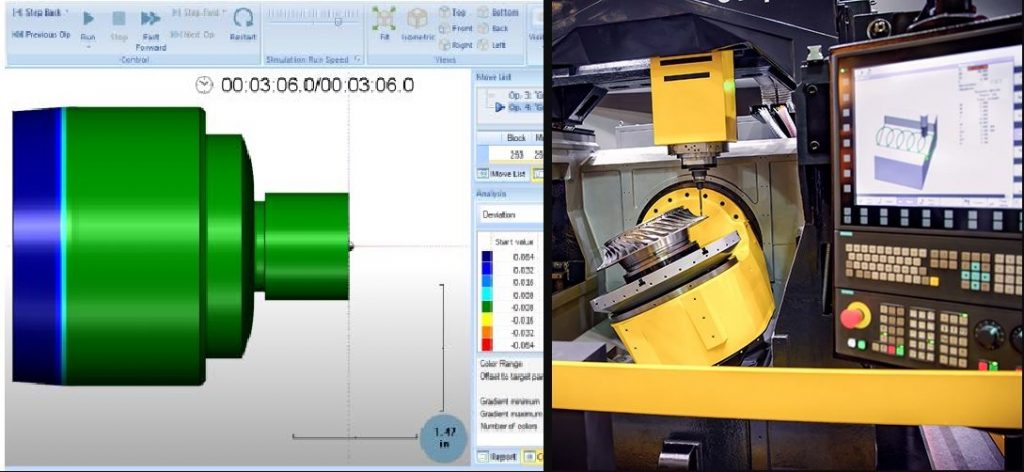

3D Designing

CAD software has become integral to modern engineering because it allows engineers and designers to create products faster than ever before with digital blueprints instead of physical prototypes. When you are creating a product that might be used in the medical or automotive industry, it becomes critical to spend time designing your machine part with the help of computer-aided design software. CAD helps cut down drastically on the cost of engineering changes later in the process, saving both time and money.

Modeling objects

It might seem impossible for those who have no prior knowledge about how factory machinery works to design a new part without having a physical prototype in front of them first. However, computer-aided design makes it possible for anyone to create a virtual replica of the object that needs to be manufactured using CAD software.

Time Reduction

When designing your part in CAD, smaller portions typically take less time to make than the overall product would. Since this machine time is spread out over multiple orders or set up times, each product takes longer to finish. By only having one design and using CNC machines capable of doing many different types of work at once, it reduces the amount of time between steps, making machining faster and more efficient.

Troubleshooting

In most cases, when you’re using CNC machines, they might break down for some reason or another. It’s a lot easier to look over the CAD file and see if there is an issue with your design, even if it didn’t cause the machine to break down. If you have used a CNC machine for cutting tools or other parts before, you might know the frustrations involved when a part does not fit correctly or a sharp edge gets ground away. With a digital copy of your product, these problems are much easier to fix before they even happen. Further, CAD can allow a machining company to work out any bugs or kinks beforehand. Therefore, there aren’t any complications during production, which results in less waste and more satisfied customers because they know what they will get.

Quality Is Easily Controlled

As long as someone with experience under normal conditions is operating the CNC machines, you can guarantee that your parts will be machined just how you want them every single time. If any mistakes happen to slip through or an inexperienced person is running the machine at that moment, it’s very easy to make adjustments with CAD because you know exactly where each line is going to be cut on your part. Whether this is done manually by using different machining techniques or by changing the initial design, it is easier to control the quality when you have a digital copy of whatever you’re making.